It’s important to choose reliable technicians for stretch wrap machine repair to ensure solid outcomes.

It’s important to choose reliable technicians for stretch wrap machine repair to ensure solid outcomes.

Blog Article

Understanding the Value of Timely Stretch Wrap Equipment Fixing Solutions

When it concerns stretch wrap makers, timely repair services can make all the difference. You know that also minor mechanical or electric concerns can cause unforeseen downtime, impacting your manufacturing line. Resolving these problems swiftly not just preserves effectiveness yet additionally increases the high quality of your covered items. So, what variables should you consider to assure your makers remain in top shape? Allow's explore this important element additionally.

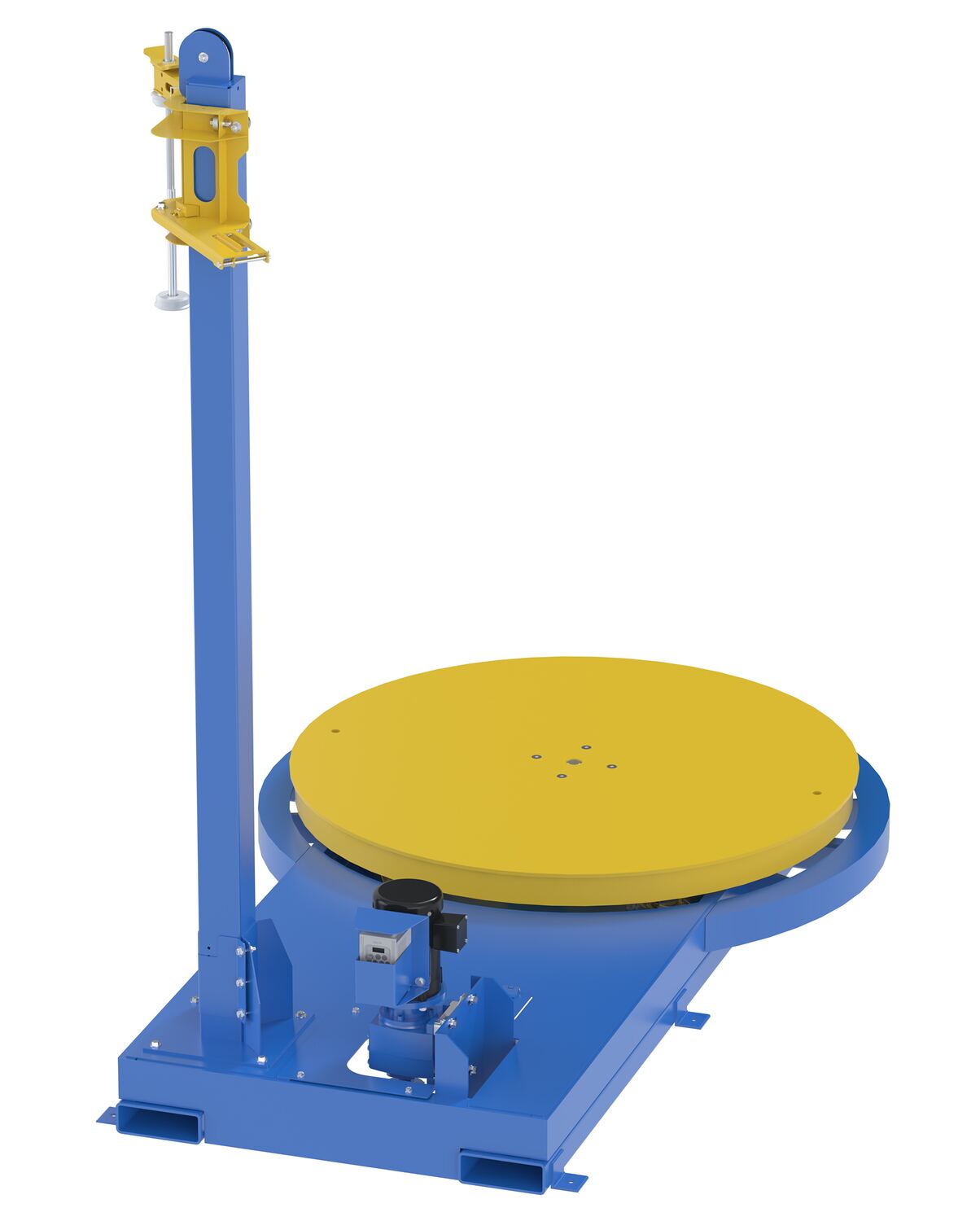

The Role of Stretch Cover Machines in Modern Manufacturing

Stretch wrap devices play a vital role in modern-day production by ensuring that products are securely packaged for transportation and storage space. You rely upon these machines to give stability and defense, protecting against damages during transportation. When you make use of stretch wrap, you minimize the risk of products moving or getting smashed, which can result in pricey losses.

Furthermore, using stretch cover equipments can boost your overall supply chain effectiveness. By simplifying the packaging process, you reduce labor expenses and accelerate shipment times, making certain that your consumers receive their products immediately. In today's busy market, this benefit is important.

Typical Issues That Result In Device Downtime

When your stretch cover equipment experiences downtime, it can commonly be mapped back to mechanical failures or driver errors. Understanding these typical concerns can aid you prevent pricey interruptions. By addressing these points, you can maintain your operations running smoothly.

Mechanical Failures and Breakdowns

Mechanical failures and failures can considerably disrupt your procedures, bring about costly downtime. These issues commonly stem from worn-out parts, such as equipments and belts, or inadequate lubrication. When components put on down or break, your stretch wrap machine might stop all of a sudden, influencing efficiency. Furthermore, electric failings can trigger malfunctions in the maker's control system, producing further delays. Normal upkeep is necessary to capture these issues early and keep your tools running smoothly - stretch wrap machine repair. Neglecting small problems can bring about bigger, more costly repairs down the line. By focusing on timely repair work, you're not just decreasing downtime yet also expanding the lifespan of your device. Stay aggressive, and maintain your operations efficient and uninterrupted.

Operator Errors and Oversights

While drivers play an essential role in the smooth functioning of your stretch wrap device, their errors and oversights can result in significant downtime. Usual concerns like improper loading, incorrect setups, and failure to monitor wrap tension can create hold-ups and item damages. If an operator forgets to inspect for worn-out film, it can lead to irregular covering and boosted waste. Additionally, miscommunication throughout changes can lead to important adjustments being forgotten. It is very important to supply detailed training and normal refreshers to decrease these blunders. Urging a society of responsibility and vigilance amongst your group can significantly minimize downtime. Eventually, buying operator training repays by improving performance and lengthening your maker's lifespan.

The Financial Impact of Delayed Repair Work

Postponing repairs on your stretch wrap device can bring about significant financial repercussions that ripple with your entire operation. When your device breaks down, performance plummets. Each hour of downtime can cost your service not simply in lost output, however likewise in labor expenditures as staff members stand still. You might likewise deal with boosted material waste as a result of inappropriate covering, causing greater expenses for packaging click supplies.

In addition, long term delays can rise small issues into significant issues, needing extra substantial repair services or perhaps total substitute of the maker. This can strain Get the facts your budget plan and disrupt capital. Delays can also affect your delivery routines, damaging customer fulfillment and potentially triggering you to shed company to competitors. Eventually, timely fixings are vital to preserving your profits and making certain smooth procedures. Don't take too lightly the monetary impact of neglecting those fixing needs.

Benefits of Proactive Upkeep Programs

Timely repair services can save you from pricey downtime, however executing a positive maintenance program takes it an action additionally. By routinely scheduling upkeep, you can identify possible issues prior to they escalate right into major problems. This not just maintains your stretch wrap machine running smoothly but additionally extends its life expectancy. You'll locate that consistent upkeep reduces the possibility of unforeseen breakdowns, permitting your operations to run extra efficiently.

Moreover, a positive approach improves performance. With less interruptions, your workforce can focus on their tasks without the anxiety of abrupt equipment failures. And also, you'll likely save on repair prices, as small issues are generally less expensive to repair than substantial fixings. Ultimately, maintaining peak efficiency can enhance the quality of your wrapped products, guaranteeing consumer complete satisfaction. Over time, a proactive upkeep program is an investment that repays via increased reliability and expense financial savings.

Recognizing Signs That Your Equipment Needs Repair

As you run your stretch wrap device, it is essential to remain watchful for indicators that indicate it may need repair. If the film isn't adhered effectively or you see uneven tension, your machine might be malfunctioning.

If your machine frequently quits or requires changes, it is time to check out. Keep an eye on the device's rate; if it's slower than common, something could be wrong.

Choosing the Right Repair Solution for Your Needs

Just how do you pick the appropriate repair solution for your stretch cover machine? Look for professionals that specialize in stretch cover equipments and have a proven track document.

Following, assess their reaction time. A dependable solution must use prompt support, as equipment downtime can be costly. It's also important to understand if they offer emergency fixings.

Don't neglect to ask about guarantees on repair services and parts. A reputable solution guarantees their job, offering you peace of mind.

Finally, compare rates however avoid picking exclusively based upon cost. In some cases, the most inexpensive option might bring about substandard service. By considering these aspects, you'll find a repair service that satisfies your demands and keeps your stretch next page cover device running efficiently.

Techniques for Decreasing Stretch Wrap Maker Downtime

Training your drivers is another vital approach. Furnish them with the understanding to recognize and deal with small problems prior to they cause significant malfunctions. Encourage them to maintain a log of any kind of irregularities, which aids in detecting problems much faster.

Additionally, maintaining a stock of important extra components can considerably minimize downtime. When something breaks, having the right components handy suggests you won't have to wait on shipments.

Last but not least, think about buying real-time surveillance systems. These systems can alert you to performance changes, permitting for instant treatment. By implementing these methods, you'll keep your stretch wrap maker running efficiently and effectively.

Often Asked Inquiries

Just How Typically Should Stretch Cover Machines Be Serviced?

You must service stretch cover equipments frequently, preferably every 6 months. However, if you discover any efficiency problems or unusual sounds, do not wait-- schedule upkeep right away to stop costly break downs and guarantee peak performance.

What Are the Normal Costs Connected With Stretch Cover Equipment Repairs?

Regular costs for stretch wrap device repair services vary, but you may expect to spend between $200 to $1,500 depending upon the issue. Regular upkeep can aid decrease these costs and extend your maker's lifespan.

Can I Do Basic Upkeep on My Stretch Wrap Device?

Yes, you can perform standard maintenance on your stretch wrap machine. Frequently examine for wear and tear, clean up the elements, and assurance proper lubrication. Maintaining it in excellent shape can extend its life expectancy and boost effectiveness.

How Do I Know if a Repair Service Is Credible?

To find a reliable fixing solution, inspect on the internet testimonials, ask for suggestions, and verify accreditations. A trusted solution will certainly supply clear quotes, warranty alternatives, and punctual communication, guaranteeing you feel great in their competence.

What Should I Perform in Situation of an Emergency Machine Break Down?

In situation of an emergency maker failure, you ought to instantly stop procedures, assess the concern, and call your repair work solution. Keep important get in touch with numbers handy, and record the trouble for effective troubleshooting when aid gets here.

Verdict

To sum up, understanding the importance of prompt stretch cover device fixings can substantially boost your procedures. Keep in mind to remain alert for indicators of wear and select a trustworthy fixing solution to keep your equipments running smoothly.

Report this page